Over the last decade, solar energy has been on a steep rise, shooting from a consumption level of 88 TWh in 2010 to 17,943 TWh in 2019. This progress is only natural as the proven benefits are being widely recognized. In fact, it is not just solar energy – all other forms of renewable energy that they now overshadow the once-leading source of energy: coal.

However, the use of solar is not without caveats. Panels, when out of use, pose a threat to the environment and, of course, the living beings that reside within it. A typical solar panel can last about 20 years, which means installations from the early 2000s are reaching the end of their lifespan. We will learn what happens to these veteran machines.

What’s in a Solar Panel?

A solar panel or photovoltaic module is made of metal framing, power-transmitting wires, protective glass sheets and plastic film, with electricity-generating silicon cells and other metals. Together, they form an energy-producing unit that converts sunlight into electricity. Nevertheless, with the presence of heavy metals, solar waste may induce terrible outcomes if waste is managed poorly.

The State of Solar Recycling

Solar panel recycling could mitigate the risk that they pose and, luckily, effective methods do exist. First Solar, America’s largest solar company, has facilities that can extract 90 percent of the material in the panels, which is then recycled back into new solar panels or electronics.

Currently, China and the U.S. are the largest users of solar panels, but only Europe has taken measures to hold manufacturers responsible for their waste.

Veolia, a French waste company, has opened the first plant in Europe solely dedicated to recycling solar cells. The problem is persuading companies to use these methods, instead of opting for the cheaper method of tossing panels into landfills.

The European Union requires solar companies to collect and recycle their panels, with the cost of recycling built into the selling price. This way, the panels’ waste and impact on the environment are minimized with only a marginal increase in solar panel price for consumers. The U.S. and China aren’t willing to adopt a similar mandate anytime soon. To date, Washington is the only state that mandates manufacturers to dispose of panels at a specialized facility.

In Asian countries, where solar energy has been thriving in the last few years, there aren’t any adequate policies to handle solar panel waste. As early as 2030, the continent risks being flooded by hazardous components from used solar panels. If leaders do nothing to change this, the core values of using solar, being sustainable and environmentally friendly, are nullified.

The Problems With Solar Panel Disposal

Most solar recycling plants simply remove the valuable silver and copper from the cells and then recycle the contaminated glass and plastic casing by burning them in cement ovens. Since the process is costly and time-consuming, it’s more convenient for solar companies to drop the dead panels into landfills or export them to third-world countries.

While a properly built landfill should contain the most hazardous material in the waste, a developing country may not have the infrastructure or regulations to properly dispose of imported solar panel waste. Potential leaching of these metals into the surrounding environment can pose a public health problem, especially in a nation without the necessary disposal infrastructure. As society continues to adopt solar power, this problem may worsen in the coming decades, with almost 80 million tons of solar waste projected by 2050.

Studies have shown the heavy metals in solar panels — namely, lead and cadmium — can leach out of the cells and get into groundwater, as well as affect plants. These metals also have a record for detrimental effects on human health. Lead is commonly known to impair brain development in children, and cadmium is a carcinogen.

Also, very pure silicon must be used because the crystal structure it forms is most conducive to letting electrons flow, which can be problematic. Despite silicon being recyclable, to improve solar cell efficiency, metals such as cadmium and lead are added. This makes them difficult to recycle since it will require much energy to extract hazardous metals. In fact, it often costs companies more to recycle a solar panel than to manufacture a new one.

Potential economic benefits

At the same time, there might be a financial opportunity hidden within the unattractive, out-of-order panels. A study by the International Renewable Energy Agency (IRENA, 2016) pointed out that in the long run, building dedicated PV panel recycling plants could yield up to $450 million by 2030 and more than $15 billion by 2050.

Yet, profitability should not be the main driver for recycling, as another research published in 2017 found that it is cheaper to landfill silicon crystalline solar panels, accounting for 80 percent of the global market than to recycle them. With the price of recovered materials shot up, developers may find it hard to resist cheaper, arguably more reliable virgin ones.

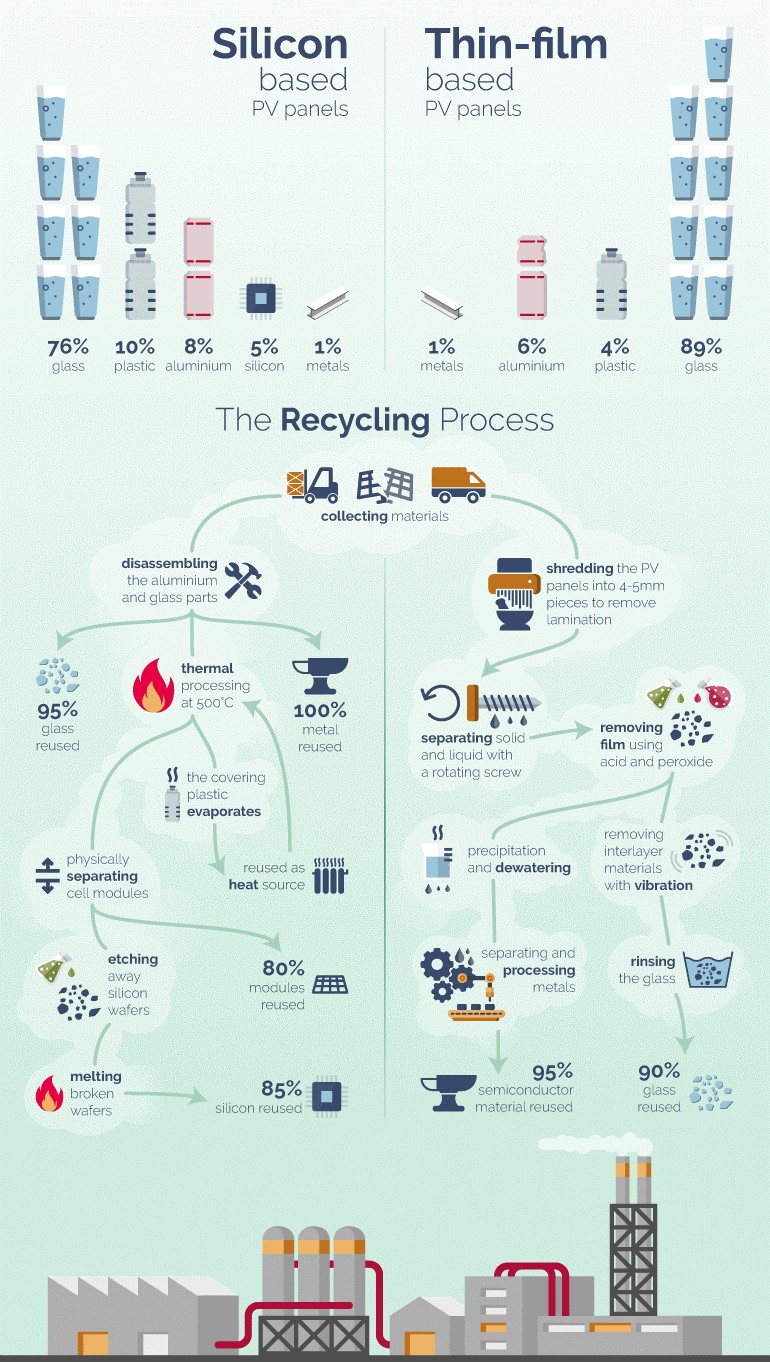

Solar modules are a medley of components such as stabilizing metal framing, power-transmitting wires, protective glass sheets and plastic membranes, as well as electricity-generating silicon cells and other metals. Recycling is burdensome and expensive, involving mechanical, thermal and chemical processes.

In the case of silicon-based panels, recovering some core components can be cost-effective, but it is tedious to extract and purify silicon and other precious metals. Recyclers must break the entire panel apart, melt components down, or even bathe materials in acidic chemicals.

Another obstacle is logistics. Solar developers sometimes operate in remote locations, while recycling facilities tend to cluster in developed areas, requiring companies to transport bulky panels over long distances.

The Recycling Process

Finally, here comes the cycle of a solar panel, illustrated by GREENWATCH: